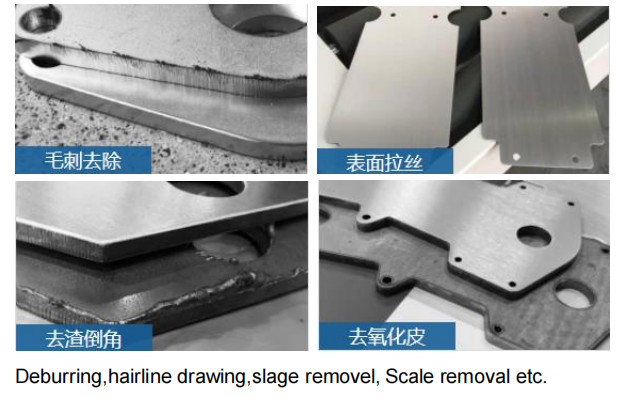

Sheet metal deburring and chamfering is an important link in sheet metal processing, which is of great significance for improving product quality and production efficiency. This paper introduces the principle, method and application of sheet metal deburring chamfering.

First, deburring

1. Deburring by hand

Manual deburring is the easiest method and is suitable for small batch production and simple parts. Operators use sandpaper, scrapers and other tools to polish the surface of the parts to remove burrs. This method is less efficient, but is suitable for small batch, simple parts.

2. Mechanical deburring

Mechanical deburring is to process the surface of parts through tools such as machine tools and grinding equipment to remove burrs. This method has high efficiency and is suitable for mass production. Mechanical deburring is divided into dry grinding and wet grinding two ways. Dry grinding is suitable for parts with high surface roughness requirements, and wet grinding is suitable for parts with low surface roughness requirements. 3. Chemical deburring Chemical deburring is the removal of burrs on the surface of parts by chemical reaction. This method is suitable for parts with small batch production and high surface roughness requirement. Chemical deburring requires the use of professional chemical reagents and equipment, the operation is more complex. 1. The role of chamfer chamfer is a processing method of the edge of the part, which can remove the sharp edge and improve the assembly performance and appearance quality of the part. Chamfering also prevents parts from being scratched or stuck during transport and use. 2. The method of chamfering is mainly divided into two kinds: mechanical chamfering and laser chamfering. Mechanical chamfering is processed by machine tools or dedicated chamfering machines, suitable for mass production. Laser chamfering is processed by laser cutting equipment and is suitable for small batch production or high-precision parts. 3. Selection of chamfer parameters The selection of chamfer parameters should be comprehensively considered according to the use, material, size and surface roughness requirements of the parts. In general, the radius of the chamfer should be determined according to the size and use of the part, and should not be too large or too small. At the same time, the depth of the chamfer should also be determined according to actual needs to ensure the assembly performance and service life of the parts. Sheet metal deburring chamfering has been widely used in automotive, aerospace, electronics, home appliances and other fields. In the automotive field, deburring chamfering is an important link in the manufacturing process of automotive parts, which can improve the appearance quality and assembly performance of parts. In the aerospace field, due to the high precision and surface quality requirements of parts, deburring chamfering is widely used. In the field of electronics and home appliances, manual deburring and chemical deburring have been widely used because of the rapid replacement of products and more small batch production. In short, sheet metal deburring chamfering is an important link in the sheet metal processing process, which is of great significance for improving product quality and production efficiency. In practical applications, the appropriate deburring method and chamfering parameters should be selected according to the specific situation to ensure the appearance quality and assembly performance of the parts.